MYOB Acumatica unites your manufacturing and distribution teams, processes, and data in one place, helping you control product quality and mitigate any issues

Integrate quality management across every facet of your business from accounting and purchasing, to manufacturing and distribution with MYOB Acumatica. Centralising your processes will increase traceability, reduce compliance risks, improve customer satisfaction and automate time consuming manual tasks.

How integrated quality management benefits your business:

- Control quality-related issues from anywhere, at anytime

- Ensure the step-by-step completion of QC tests

- Monitor materials in real-time to maintain quality and compliance

- Ensure timely process tracking with automated workflows

- Establish embedded library of standardised QC tests, control plans and compliance documentation

- Execute inspection plans, checklists and QC tests against products, people and equipment

- Auto assign lot statuses and disposition lots, based upon QC results

- Analyse QC tests by item, lot, job and vendor

- Improve auditing capabilities

- Support NC & CAPA processes

- Reduce rework costs

- Streamline operations

- Strengthen collaboration

- Increase customer satisfaction

Quality Control is a critical part of the manufacturing process, and a highly important function for industries such as:

- Manufacturing

- Food and beverage

- Medical and life sciences

- Aerospace

- Automotive

- Oil, gas and chemicals

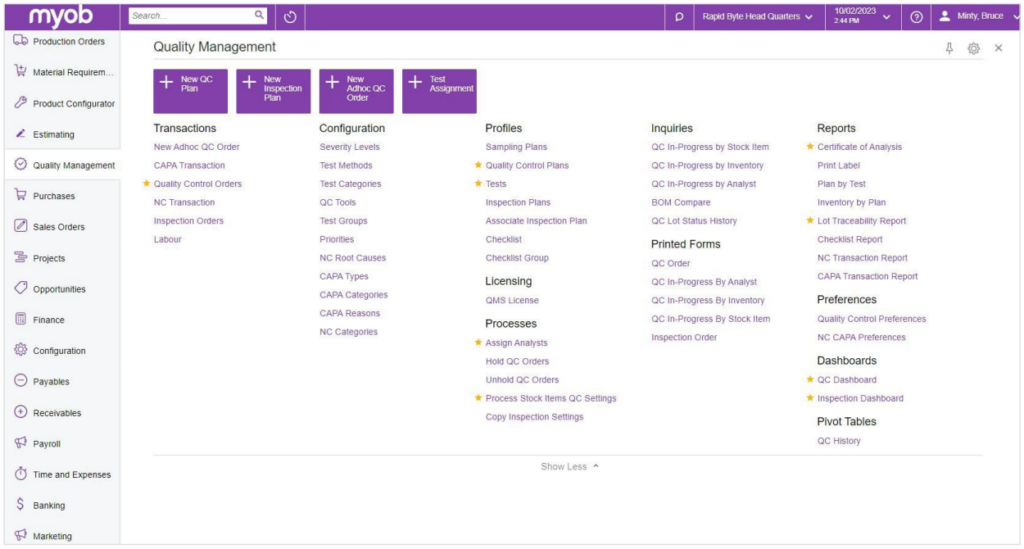

MYOB Acumatica – Quality Management

Features and benefits

Quality

Management

Perform end-to-end QC testing for incoming raw materials, production, purchasing, inventory and shipping.

Checkpoints and Inspections

Execute inspection plans, checklists, and QC tests against products, people, and equipment.

Certificate of Analysis (COA)

Generate COA and production deviation documents and reports.

NC and

CAPA

Track non-conformances, maintain a complete audit trail, and manage corrective and preventive action processes.

AQL and

Sampling

Carry out 100% inspection or sampling routines (AQL and non-AQL).

Traceability and Recall Notices

Implement forward and backward tracing of all movements of a serial or lot number.

Packaging Bills of Material

Assign QC tests to sub-assemblies and finished goods that are executed and validated during production.

Lot-Based Quality Control

Perform quality control testing based on individual lots.

Mobile Data

Collection

Conduct QC and capture data from any location via mobile and web.

Reporting and

Analytics

Report with user-friendly and pre-built reports for vendor, production, and stability analytics.

Education &

Training

Manage the training process and keep employee and training records organised, up-to-date, and compliant.

Supplier/Vendor Management

Evaluate, score, and summarise the activity and performance of your suppliers/vendors.

Audit

Management

Support the complete audit from beginning to end in compliance with corporate standards and industry regulations.

Health and

Safety

Store, manage, and access required health and safety records.