ATP Science

Manufacturing

“The impact MYOB Acumatica has had on the business was apparent from day one and ATP has only just started realizing its full capabilities”.

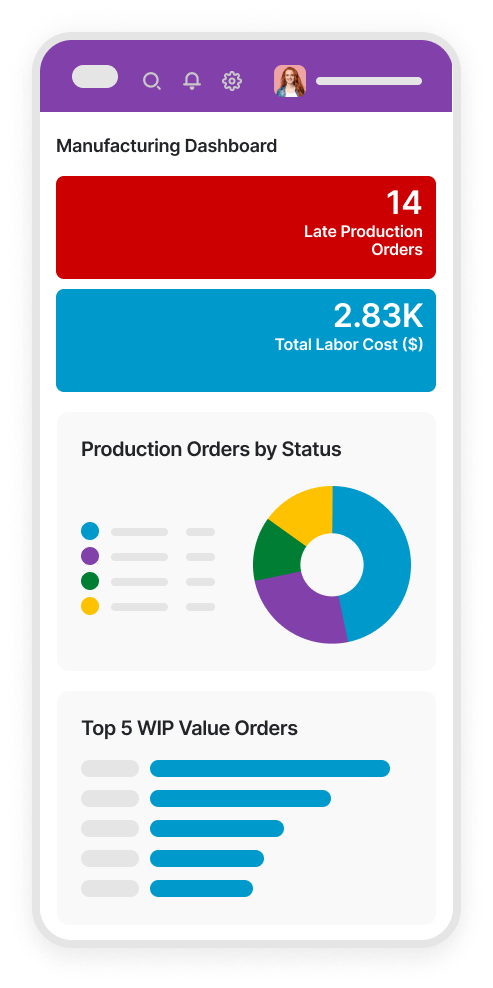

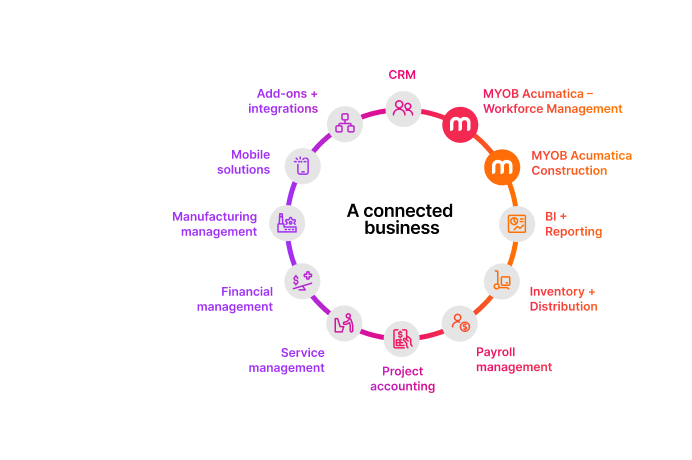

Your complete cloud-based manufacturing solution

MYOB Acumatica Manufacturing is designed specifically for Australian manufacturers enabling you to efficiently manage your entire business end-to-end using one system. It integrates manufacturing, inventory management and accounting to help businesses ensure raw materials are available to production, efficiently manage the manufacturing process, maintain revisions, and track the financials.

Be able to streamline business processes, generate accurate pricing, and calculate your total manufacturing costs using one up-to-date, accurate and reliable system.

Plan and coordinate effectively

Reduce product complexities

Balance supply and demand

Improve collaboration

Some of our Manufacturing Clients

We have a system that can manage our manufacturing and distribution processes in one package, but more importantly, we know that we can trust our data – that’s a massive relief

– Toni Doige, Director – ATP Science

Supported Manufacturing Types

Industrial

Gain visibility and efficiency across your supply chain, whilst improving quality, innovation and time to market.

Metal Fabrication

Provide better service and more sophisticated products, and deliver with speed and accuracy.

Instruments/ Electronics

Plan and coordinate your manufacturing operations, whilst effectively managing supply and demand.

Food & Beverage

Streamline your manufacturing processes, gain visibility and control of your inventory, whilst improving quality.

Explore More

Automotive

Provide better products and services, while continuing to innovate, adapt and invest in the latest technology.

Medical Device

Meet the demands for product traceability and innovation, while future-proofing your supply chain.

Aerospace

Gain greater insights into your operations, while maintaining sophisticated execution.

Cosmetics

Leverage the power of visibility, to support continuous innovation and development to gain a competitive advantage.

MYOB Acumatica Quality Management

Integrate quality management across every facet of your business from accounting and purchasing, to manufacturing and distribution with MYOB Acumatica. Centralising your processes will increase traceability, reduce compliance risks, improve customer satisfaction and automate time consuming manual tasks.

Unify your business operations in one scalable platform

See MYOB Acumatica Manufacturing in action

Watch our free demo to see some of the capabilities and features within the powerful MYOB Acumatica platform

Customer Stories

“The impact MYOB Acumatica has had on the business was apparent from day one and ATP has only just started realizing its full capabilities”.

“As we develop more products and the orders start to come in, we can process them accurately and timely with MYOB Acumatica”.

“I haven’t spoken to anyone that MYOB Acumatica wouldn’t work for, purely because of the scalability of it”.

“With accurate inventory control and management, now we can accurately track our inventory from start to finish and it’s all on one platform”.